This information has been extracted from Lotus Service Notes part number B082T0327J

Preamble

Tasks such as fitting a new water pump, cylinder head gasket replacement, adjusting tappet clearances and routine replacement of the timing belt all have the potential to disturb both cam and auxiliary shaft timing.

Therefore before attempting to adjust the distributor orientation it is advisable to check the position of the timing pulleys.

This should be carried out with the engine at Top Dead Centre (TDC)

If a fully assembled engine is being checked then No1 cylinder must be on the compression stroke with all four valves closed.

This position can be easily established by removing the cam covers and examining the position of the camshaft lobes

When No1 cylinder is at TDC on the compression stroke, the camshaft lobes will point directly away from No.1 spark-plug

From experience, if the auxiliary timing pulley is out of phase be one or two teeth, then it will be almost impossible to adjust the distributor to its correct position.

This situation can lead to the following -

1) Ignition timing significantly retarded that will make the engine difficult to start, poor idle speed, poor throttle response and lack of power.

2) Ignition timing significantly advanced that has the potential to create detonation problems and in turn damage internal engine components.

Lotus Service Notes, Section EB

4. Turn the engine to No.1 (firing) TDC using the timing marks and pointer on the flywheel rim and clutch housing, with the cam pulley timing marks facing towards each other. In this position, note or mark the position of the auxiliary shaft pulley.

Lotus Esprit pulley timing marks

Lotus Esprit pulley timing marks

Page 10

Lotus Service Notes, Section EW.8 - Idle speed and ignition timing setting procedure

i) Ignition Timing Initial Setting:

If the engine has been rebuilt, or the distributor replaced, an initial setting of the ignition timing must be made to enable the engine to run.

Set the crankshaft to 10° by using the timing marks and pointer on the flywheel and clutch housing, with the rotor arm pointing towards No. 1 terminal on the distributor cap.

Pull off the rotor arm and plastic shield and turn the distributor body to align the pick up sensor with the adjacent projection on the reluctor (equivalent to the cam on a contact breaker system).

The engine may now be started and run up to normal operating temperature before adjusting ignition timing as in ii)

Page 7

Lotus Esprit distributor orientation

Lotus Esprit distributor orientation

ii) Check/Adjust Ignition Timing:

Start the engine and run up to normal operating temperature to ensure the T.I.V. switches the distributor capsule to the throttle edge port.

Using a stroboscope, check/adjust the ignition timing to 10°BTDC at hot idle.

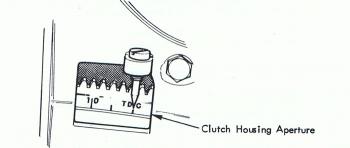

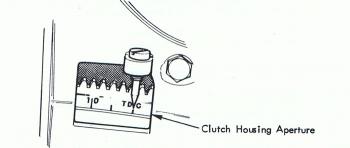

Timing marks are provided on the flywheel rim, with an aperture and pointer in the top of the clutch housing, adjacent to the starter motor.

Pull out the protective grommet, and refit after adjustment.

Lotus Esprit flywheel timing marks

Lotus Esprit flywheel timing marks

To check the centrifugal advance operation, first disconnect and plug, or clamp off the vacuum hose between distributor capsule and T.I.V.

Check centrifugal advance characteristics are as follows:

Crank rpm Crank° (+ - 2°)

Below 1,000 nil

2,000 8

3,000 16

Page 8

Preamble

Tasks such as fitting a new water pump, cylinder head gasket replacement, adjusting tappet clearances and routine replacement of the timing belt all have the potential to disturb both cam and auxiliary shaft timing.

Therefore before attempting to adjust the distributor orientation it is advisable to check the position of the timing pulleys.

This should be carried out with the engine at Top Dead Centre (TDC)

If a fully assembled engine is being checked then No1 cylinder must be on the compression stroke with all four valves closed.

This position can be easily established by removing the cam covers and examining the position of the camshaft lobes

When No1 cylinder is at TDC on the compression stroke, the camshaft lobes will point directly away from No.1 spark-plug

From experience, if the auxiliary timing pulley is out of phase be one or two teeth, then it will be almost impossible to adjust the distributor to its correct position.

This situation can lead to the following -

1) Ignition timing significantly retarded that will make the engine difficult to start, poor idle speed, poor throttle response and lack of power.

2) Ignition timing significantly advanced that has the potential to create detonation problems and in turn damage internal engine components.

Lotus Service Notes, Section EB

4. Turn the engine to No.1 (firing) TDC using the timing marks and pointer on the flywheel rim and clutch housing, with the cam pulley timing marks facing towards each other. In this position, note or mark the position of the auxiliary shaft pulley.

Lotus Esprit pulley timing marks

Lotus Esprit pulley timing marksPage 10

Lotus Service Notes, Section EW.8 - Idle speed and ignition timing setting procedure

i) Ignition Timing Initial Setting:

If the engine has been rebuilt, or the distributor replaced, an initial setting of the ignition timing must be made to enable the engine to run.

Set the crankshaft to 10° by using the timing marks and pointer on the flywheel and clutch housing, with the rotor arm pointing towards No. 1 terminal on the distributor cap.

Pull off the rotor arm and plastic shield and turn the distributor body to align the pick up sensor with the adjacent projection on the reluctor (equivalent to the cam on a contact breaker system).

The engine may now be started and run up to normal operating temperature before adjusting ignition timing as in ii)

Page 7

Lotus Esprit distributor orientation

Lotus Esprit distributor orientationii) Check/Adjust Ignition Timing:

Start the engine and run up to normal operating temperature to ensure the T.I.V. switches the distributor capsule to the throttle edge port.

Using a stroboscope, check/adjust the ignition timing to 10°BTDC at hot idle.

Timing marks are provided on the flywheel rim, with an aperture and pointer in the top of the clutch housing, adjacent to the starter motor.

Pull out the protective grommet, and refit after adjustment.

Lotus Esprit flywheel timing marks

Lotus Esprit flywheel timing marksTo check the centrifugal advance operation, first disconnect and plug, or clamp off the vacuum hose between distributor capsule and T.I.V.

Check centrifugal advance characteristics are as follows:

Crank rpm Crank° (+ - 2°)

Below 1,000 nil

2,000 8

3,000 16

Page 8