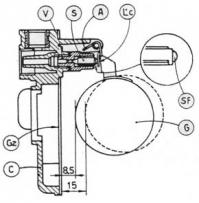

DIRECTIONS FOR LEVELLING THE FLOAT

It's essential that the following direction be complied with in order to obtain correct levelling of the float:

- Make sure that the weight of the float (G) is the correct one (26 grams) that float can freely slide on the axis and doesn't show any pit.

- Make sure that needle valve (V) is tightly screwed in its housing and that pin ball (Sf) of the dampening device, incorporated in the needle (S), is not jammed.

- Keep the carburetor cover (C) in vertical position as indicated in figure since the weight of the float (G) could lower the pin ball (Sf) fitted on the needle (S).

- With carburetor cover (C) in vertical position and float clip (Lc) in light contact with the pin ball (Sf) of the needle (S), the distance of both half¬floats (G) from upper surface of carburetor cover (C), without gasket, must measure 8.5mm.

- After the levelling has been done, check that the stroke of float (G) is 6.5 mm. If necessary adjust the position of the lug (A).

- Should the float (G) not be correctly placed, modify the position of the tabs (Lc) of the float until the required point is reached, taking care that the tab (Lc) is perpendicular to the needle axis (S) and that it doesn't have any indentations on the contact surface which might affect the free movement of the needle itself.

- Fit up the carburetor cover making sure that float can move without any hindrance or friction.

NOTE - The operations of levelling of float must be carried out whenever it is necessary to replace float or needle valve. At the same time it is advisable to replace the sealing gasket, making sure that the new needle valve is tightly screwed in its housing.