Introduction

This document was originally written to provide assistance to Lotus Elan and Elan +2 owners who experience problems when attempting to diagnose overheating problems.

However, much of this information and general principles are applicable to other Lotus vehicles such as the Esprit, Eclat, Europa etc.

The radiators fitted during production provided adequate cooling for a given power output from the Ford/Lotus Twin Cam engine when installed in the relevant vehicle.

Overheating is not usually a problem with the standard Elan or Elan +2 providing the cooling system is correctly maintained and there are no major engine performance modifications.

Stories of overheating problems can often be directly attributed to inappropriate modifications and lack of cooling system maintenance.

Over the years various radiators have been used as substitutes in the Lotus Elan and Elan +2.

This type of modification has been met with varying degrees of success as most owners are not aware of the calculations to determine the heat dissipation of any donor radiator.

One popular and successful replacement is to install a VW Golf radiator in to a Lotus Elan.

However this involves modifying the cooling system so the radiator is inclined at an angle within the nose of the car.

This type of installation is common where a standard road car is converted to a light weight racing Elan.

This conversion moves the aluminium alloy radiator forward directly into the path of the incoming air-stream and improves cooling capabilities.

The Lotus Factory developed various improvements, and these included cooling modifications to the Elan +2 (see the Lotus Elan workshop manual, section K12, page 12).

This cooling improvement consisted of the addition of blanking panels either side of the radiator mounting brackets and below.

In addition to this, foam strips were glued to the underneath of the bonnet to ensure all air entering the front of the car was forced through the radiator (rather than escape in the gaps around the radiator).

This modification is also recommended for the Lotus Elan.

If you have an original radiator, then it may be feasible to install an efficient modern day cooling matrix within the header tank and fixing points.

Alternatively it is possible to install a purpose built (and correctly designed) after market aluminium alloy radiator.

These items are expensive but offer the benefit of additional cooling capacity plus a significant weight saving.

Overheating problems are not a single source problem and therefore are not just confined to the radiator.

Quite often after lengthy investigations, the fault can be traced to other components within the cooling system or an engine that has been substantially modified.

Radiator construction

There are some basic checks and simple modifications that can be made to significantly improve the cooling system in any Lotus Elan.

First check what type of radiator is installed in the vehicle.

This may sound rather obvious but with the passage of time, various types of radiators may have been substituted.

These may or may not be capable of providing adequate cooling.

The original Elan and Elan +2 radiators have a two core construction.

This means that two rows of vertical cooling tubes run through the cooling matrix.

This can be checked by removing the radiator cap and counting the number of rows visible at the top of the radiator tank.

The rows are usually staggered and should be counted across the cooling matrix (from front to rear).

It is also possible to up rate the radiator capacity by changing the standard two cores to a three core construction.

This simple modification is recommended in warmer climates or if the engine has been modified to produce more power.

Radiator types

During production there were several radiators that were fitted to the Lotus Elan and Lotus Elan +2.

The following list provides part numbers and models to receive these components.

026K0001 – fitted to Lotus Elan S1, S2, up to chassis number 5810 (bottom fastening)

A026K0001 – fitted to Lotus Elan S3, from chassis number 5811 to 7894 (full width @ 22 inches, with side fastening)

A050K0001 – fitted to Lotus Elan S4, from chassis number 7895 onwards (narrow @ 16 inches, with side mounting brackets)

A026K0001 – fitted to Lotus Elan +2, up to chassis number 0927 (full width @ 22 inches, with side fastening)

A050K0001 – fitted to Lotus Elan +2s, from chassis number 0928 onwards (narrow @ 16 inches, with side mounting brackets)

Note- As the engine horse-power increased, radiator sizes got smaller and pressure caps were increased from 7lbs to 10lbs

Radiator sizes

Dimensions for radiator part number A050K0001 are as follows-

Overall height (bottom to top tank) is 340mm

Total height (including guard at the filler cap, if fitted) is 365mm

Width is 406mm (16 inches)

Active cooling matrix dimensions are 380mm x 250mm

From experience, it is still possible to obtain a high quality copper matrix that has three cores to provide additional cooling.

Be sure to ask for a copper matrix that has sixteen fins per inch so maximum cooling is achieved.

Radiator performance

To check the radiator performance, first run the engine until it reaches normal operating temperature.

By comparing the temperature differential between the inlet and the outlet, it is possible to assess the cooling efficiency.

With the engine at idle speed and the thermostat fully open, there should be a temperature difference of least 10 degree Centigrade.

This can easily be checked by use of a hand held, non-contact, infra-red thermometer.

Raytek manufacture an inexpensive unit known as a MiniTemp MT4.

This hand held instrument is easy to use and has a back-light digital display and incorporates a laser pointer.

Alternatively there are adapters available from Fluke Instruments that will convert their range of multi-meters into a contact type digital thermometer.

Thermostat

If the engine is showing signs of overheating, then one of the simplest tasks to carry out is to reverse flush the radiator and the rest of the cooling system.

The use of a flushing agent is also recommended as this removes calcified deposits which reduce heat transfer.

Lotus originally fitted several different thermostats to both the Lotus Elan and Lotus Elan +2.

The following list provides details of the part numbers and opening temperatures.

036E6002 thermostat – 88 degrees Centigrade

036E6003 thermostat – 71 degrees Centigrade

036E6022 thermostat – 78 degrees Centigrade

It is important to install the correct thermostat to suit climatic conditions otherwise the engine can not operate at its optimum running temperature.

To illustrate this point, interior cabin heaters will not function correctly during the cold winter months (temperatures of zero degrees and below in the Northern Hemisphere) if a 74 degree thermostat is fitted.

In simple terms this means, the engine cannot reach its designed operating temperature when a lower opening temperature thermostat fitted.

For warmer climates such as in Australia, it is recommended a 71 or 74 degree Centigrade unit be installed.

This phenomenon brings about the change and use of a “winter thermostat” and a “summer thermostat”.

Check and make sure there is a thermostat installed in the housing.

The cooling system needs a thermostat to modulate the flow of water to keep the cylinder head at an optimum operating temperature.

Check that the thermostat opens fully when placed in a pan of boiling water.

Quick opening thermostats such as WAXSTAT are highly recommended.

Thermostat specifications and testing

A thermostat that has a stamped marking of 82°C , relates to the crack point of the thermostat or when it begins to open, (SAE specification has a + / - 2.5°C tolerance on this temperature).

The fully open temperature is usually 12°C above the crack point (i.e. for a 82°C this will be approx 94°C)

The fully open position is the maximum opening position of the thermostat and should ¼ the size of the thermostat orifice (i.e. if the orifice of the thermostat is 20mm then maximum opening will only be 5mm)

During installation it is important that the correct coolant mix is used and all air is removed from the cooling system.

The thermostat requires liquid around the bulb to ensure an even temperature rise so the thermostat can open smoothly and at the correct temperature.

Air locks behind the thermostat may cause the thermostat to open at the incorrect temperature and or open and close quickly (shuddering).

A thermostat may be tested by suspending it by a thread through the orifice in cool water / coolant.

The water / coolant must be heated gradually to simulate the vehicle operation.

The thermostat will fall from the thread once the opening temp has been achieved.

See above for opening temp and maximum opening details.

NOTE: The thermostat should be replaced if it fails to open at a temperature greater than 6°C above or opens 3°C below the designated opening temperature.

Fans

To improve cooling efficiency, remove the plastic or metal fan fitted to the water pump drive flange and fit an electric thermostatically controlled fan.

When fitting an electric fan to an Elan or Elan +2, make sure the fan is offset towards the passenger side of the radiator.

Lotus got this position right on the S4 Elan and the Elan +2 S130.

Off-set mounting the fan in this way provides useful additional cooling to the alternator.

In addition to this, the air flow continues over the exhaust manifold and assists in reducing under bonnet temperatures.

Checking fans

Check and make sure the electric fan(s) rotates in the correct direction.

It should pull air in from the front of the vehicle and blow it through the radiator, where it should exit rearwards around the engine.

Also check the operating temperatures at which the thermostatically operated switch opens and closes.

The standard fan switch is known as an “Otter Switch”.

This same switch is also fitted to the Lotus Esprit, Elite and Eclat.

This switch is still available and can be purchased from Lotus Marques.

Otter switch – standard opening and closing temperatures

87 degrees C it closes and switches on the electric fan

82 degrees C it opens and switches off the electric fan

Intake airflow

Make sure the lower blanking panel is in place between the body and the bottom of the radiator (this should cover the steering rack).

The Lotus part number for the Elan lower blanking panel is B036K0076 and the Lotus part number for the Lotus Elan +2 is A050K0081.

So many of these panels which were originally manufactured from cardboard that was impregnated with Bitumen have rotted away or have been discarded.

Once removed, a vast amount of incoming air is allowed to escape between the bottom of the radiator and fibreglass panel located on top of the steering rack mounting.

Aluminium blanking panel available from Lotus Marques

Aluminium blanking panel available from Lotus Marques

If you have the original remote air filter and canister, relocate this so it’s lying down instead of standing upright and obscuring the radiator.

Stick a soft foam rubber strip across underside of the bonnet lid so when it closes it seals the gap between the bonnet and the top of the radiator.

The idea is to force all the incoming air through the radiator and not allow any to escape around it.

Imroving the cooling system on a Lotus Elan +2

Lotus recognised there were cooling issues and the workshop manual contains the following useful information-

PAGE 12 SECTION K - COOLING SYSTEM

To further improve the cooling system, 'Sl30‘ models were fitted with a blanking panel (Part No. A050K0081) below the radiator, and panels at each side of the

radiator (Part No. A050K0082 R/H; A050KO083 L/H).

ln conjunction with the blanking panels, foam rubber strips (Part number A05K0084 L/H; A050K0085 R/H), are attached to the underside of the bonnet.

Temperature gauges

The Lotus Elan is fitted with a dual gauge which incorporates the temperature gauge and oil pressure.

The temperature gauge is a capillary type and is reasonably accurate.

This needs to be installed carefully as the copper tube is prone to being damaged.

The Lotus Elan +2 is different as it is fitted with an electrical type temperature gauge.

The temperature gauge is operated by a temperature sender unit located in the cylinder head/thermostat housing.

Checking temperature gauges

Check the gauge reading against a hand held thermometer.

These devices are quick and accurate to use.

The MiniTemp MT4 can simply be pointed directly at the thermostat housing to obtain an instant engine temperature reading.

An alternative check is to remove the radiator cap (when the engine is cold) place a cooking thermometer in the top of the radiator and warm the engine up.

Check the thermometer reading against the vehicle gauge reading.

The original electrical temperature gauge and transmitter fitted to the Lotus Elan +2 and Lotus Elan +2s 130/5 are not very accurate.

Running a basic test on one particular Lotus Elan +2s 130/5 revealed the temperature gauge read eight degrees too high.

Fortunately it is better that the gauge reads too high than too low as this usually prompts the owner to take action.

The instrumentation in early Lotus vehicles is very basic.

How many Lotus owners ever think about checking the accuracy of these important devices?

Smiths Industries in the UK manufactured the original temperature transmitter.

Alternative temperature transmitters offered by companies such as VDO are incorrectly substituted.

Incorrectly substituted VDO temperature transmitter

Incorrectly substituted VDO temperature transmitter

The direct result of this will cause the temperature gauge to give a false reading, indicating the engine is either overheating or not up to normal operating temperature.

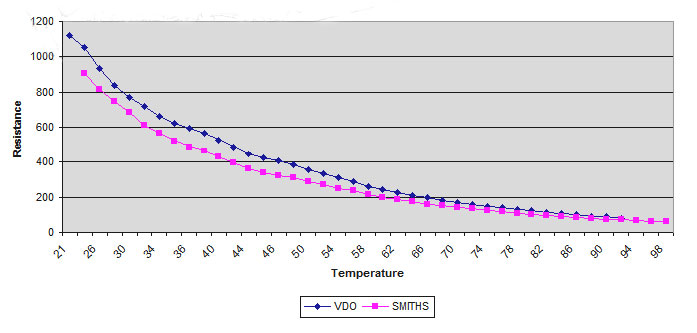

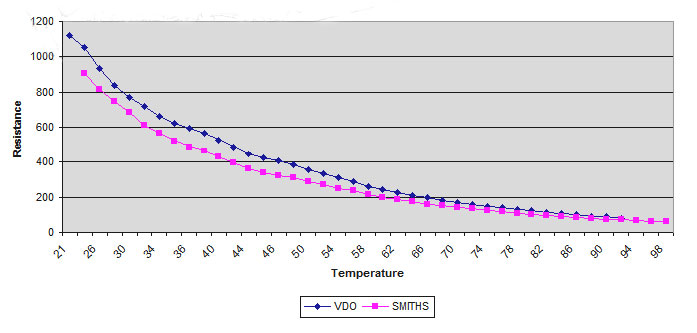

The temperature transmitter has a negative co-efficient characteristic.

In other words the resistance decreases as the temperature increases.

A comparison between a VDO and Smiths temperature transmitter is shown in the graph below.

Note: A small change in resistance represents a significant change on the temperature gauge reading.

This point illustrates why the correct component should always be installed.

Temperature transmitter characteristics

Temperature gauge and voltage stabiliser

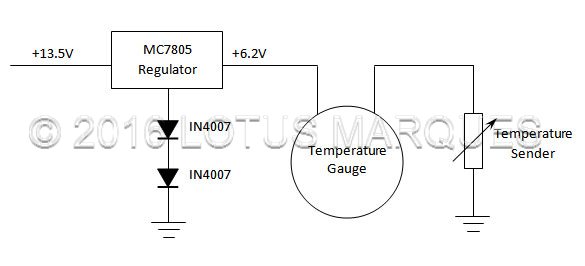

The accuracy of the temperature gauge is influenced by the original mechanical vibrating contact type voltage stabiliser.

This device is crude as it generates a square wave output in an attempt to stabilise a constantly fluctuating battery voltage when the alternator is driven by the engine.

On a Lotus Elan 2+2, both the fuel gauge and and temperature gauge share the output from the same voltage stabiliser.

Eventually the voltage stabiliser vibrating contacts wear out which in turn causes the fuel and temperature gauge to read incorrectly.

If for any reason both the fuel gauge and temperature gauge are suspected of not reading correctly then its wise to check the voltage stabiliser.

Voltage measurements must be carried out using a True RMS Digital Multi-Meter (DMM) otherwise inaccurate readings will result.

Note carefully, not all DMM's are created equal and for this reason we choose to use high quality Fluke meters.

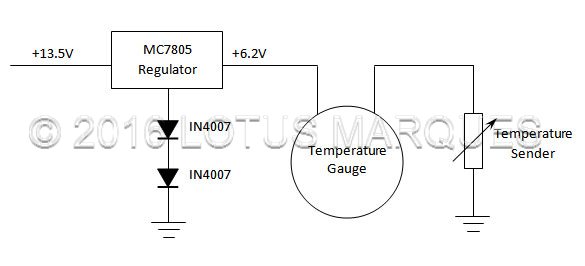

An inexpensive replacement solid-state voltage stabiliser can be constructed using the following components shown in the circuit below.

This circuit is inherently stable when subjected to a fluctuating battery voltage and changes in ambient temperature.

The same circuitry can also be used in the later Lotus Esprit (1980 onwards) that employ Smiths instruments.

Note - A correctly operating temperature sender unit should have a resistance reading of approximately 100 Ohms at 85 degrees Centigrade.

Water pump

If the water temperature continues to rise up at speed, then there are a number of items that should be checked.

Firstly, the Lotus twin cam water pump should be checked that it is not cavitating at high speed.

To do this, a water pump efficiency test should be carried out.

If the pump is cavitating then it will not produce the necessary head to move the water around the system.

Other items that influence water pump efficiency, is whether the impellor gap has been set correctly when the water pump was last rebuilt.

The water pump drive belt should also be checked for serviceability and that it is adjusted to the correct tension.

Water pump leaking from weep hole

If there is any coolant originating from the weep hole, this is a sure sign of internal seal failure.

The service life of the seal can be significantly extended by performing regular maintenance of your cooling system.

Periodic checks of hoses and the recovery tank will assure coolant levels are correctly maintained.

The correct coolant level ensures that there no atmospheric contaminants that can cause oxidation and sludge build-up in the cooling system.

Sludge build-up in the cooling system is the primary cause of seal failure as well as reducing cooling system efficiency.

Servicing the radiator

Check that the radiator fins are not blocked externally.

It may be necessary to clean the radiator with a high pressure cleaner.

Apply the pressure cleaner from inside the engine bay so it blows the trapped debris outwards to the front of the vehicle (the opposite direction to which they entered).

It is amazing how much rubbish gets trapped in a radiator and reduces its efficiency.

Inspect the condition of the black paint after pressure cleaning the radiator, you may find that sheets of paint may have peeled off.

Repaint the radiator with a good quality matt black paint.

This dramatically improves the efficiency or rate at which the radiator dissipates radiant heat.

Lotus Marques highly recommends Wattyl spray pack paint for repainting tired or refurbished copper radiators.

The product to look for is Wattyl Killrust High Heat Enamel and is ideal for radiators as it offers the following benefits -

Radiator cap

Ensure that the radiator cap is in good working order and tested to recommended pressure rating.

The radiator cap is an extremely important component in the cooling system, a faulty cap can cause overheating through the incorrect pressure rating and or loss of coolant.

Check that the correct pressure cap is installed.

Check if the cap is leaking and whether the rubber seal is serviceable.

Check the cap plunger length is correct for the radiator neck.

Early cars had a cap rated at 7lbs but this was later upgraded to 10lbs.

If the cooling system is loosing water and the pressure cap is found to be serviceable, then there is the possibility that the problem is a leaking head gasket.

This will cause the system over pressurise and dump water.

Faulty head gasket

A leaking head gasket will cause overheating problems by displacing coolant whilst the cooling system is attempting operate at normal pressure.

The easy way to check for a leaking head gasket is to carefully remove the cap and look for air bubbles whilst the engine is running.

If you have access to a gas analyser, then this can be used to check the contents of the bubbles for exhaust gases.

Alternatively a leak down tester may be used to introduce compressed air into the cylinders one at a time.

Again remove the radiator cap and look for bubbles to determine if the head gasket is leaking.

Coolant check

If over heating persists, then use a hydrometer to check the coolant concentration.

It is possible to have a significantly concentrated glycol solution in your cooling system and this will cause the engine to over-heat.

To illustrate this point, plain water has twice the heat transfer capability compared to 50% glycol antifreeze/coolant in water.

Empty the system of glycol, flush, then refill with water and check the system performance again.

For superior results, install Redline Water Wetter in your cooling system to further reduce cylinder head temperatures.

In race applications, the use of Water Wetter will allow the use of smaller and subsequently lighter weight cooling system components.

Engine modifications

If an engine is modified for race purposes, then be aware of the following calculations.

If you are going to raise the horse power of the engine by say 10bhp (this may not seem a lot) but it has a significant impact on the cooling system.

Ten brake horse power equates to approximately 7500 watts off energy.

If you have a reasonably efficient engine, then it will convert about a 33% of the available energy in to useful energy at the flywheel.

Another 33% will disappear out of the exhaust pipe and the remaining 33% will be dissipated by the cooling system.

This means the cooling system has to be capable of dumping an additional 2500 watts of energy.

This is equivalent to the heating capacity a domestic electric kettle.

Additional cooling

For performance modifications or operation in hotter climates, it is recommended that a ten or thirteen row oil cooler be fitted to engines.

This simple modification provides significant additional cooling to all the engine components.

Heat-Soak Pump

The addition of a heat soak pump is a useful way of improving engine reliability.

This simple but effective modification will minimise the risk of warping the alloy cylinder head.

The introduction of a 12 Volt boat bilge pump into the heater hose circuit would produce the desired results.

This could be easily connected to the Otter switch to control the temperature when the pump turns on and off.

A similar heat soak pump is installed on the Lotus Elan M100 as standard equipment and is manufactured by Bosch, part number 0-130-002-066.

About the author

Steve Taylor: is the business owner of Lotus Marques who has a multi-discipline background. This includes 12 years engineering experience gained whilst working on weapon systems design and development for UK Department of Defence. He has also worked for 7 years in a cutting-edge American super-computer company Gould CSD as the UK southern region support manager. During this time he developed a passion for Lotus Cars and motor racing at Brands Hatch Racing School. Emigrating from the UK to Australia in 1987, where in 1992 Lotus Marques commenced trading as a specialist parts supplier. The business offers log-book servicing and repairs as well as designing and manufacturing a range of high quality components to support Lotus owners world-wide.

Copyright © 2011 Lotus Marques

This document was originally written to provide assistance to Lotus Elan and Elan +2 owners who experience problems when attempting to diagnose overheating problems.

However, much of this information and general principles are applicable to other Lotus vehicles such as the Esprit, Eclat, Europa etc.

The radiators fitted during production provided adequate cooling for a given power output from the Ford/Lotus Twin Cam engine when installed in the relevant vehicle.

Overheating is not usually a problem with the standard Elan or Elan +2 providing the cooling system is correctly maintained and there are no major engine performance modifications.

Stories of overheating problems can often be directly attributed to inappropriate modifications and lack of cooling system maintenance.

Over the years various radiators have been used as substitutes in the Lotus Elan and Elan +2.

This type of modification has been met with varying degrees of success as most owners are not aware of the calculations to determine the heat dissipation of any donor radiator.

One popular and successful replacement is to install a VW Golf radiator in to a Lotus Elan.

However this involves modifying the cooling system so the radiator is inclined at an angle within the nose of the car.

This type of installation is common where a standard road car is converted to a light weight racing Elan.

This conversion moves the aluminium alloy radiator forward directly into the path of the incoming air-stream and improves cooling capabilities.

The Lotus Factory developed various improvements, and these included cooling modifications to the Elan +2 (see the Lotus Elan workshop manual, section K12, page 12).

This cooling improvement consisted of the addition of blanking panels either side of the radiator mounting brackets and below.

In addition to this, foam strips were glued to the underneath of the bonnet to ensure all air entering the front of the car was forced through the radiator (rather than escape in the gaps around the radiator).

This modification is also recommended for the Lotus Elan.

If you have an original radiator, then it may be feasible to install an efficient modern day cooling matrix within the header tank and fixing points.

Alternatively it is possible to install a purpose built (and correctly designed) after market aluminium alloy radiator.

These items are expensive but offer the benefit of additional cooling capacity plus a significant weight saving.

Overheating problems are not a single source problem and therefore are not just confined to the radiator.

Quite often after lengthy investigations, the fault can be traced to other components within the cooling system or an engine that has been substantially modified.

Radiator construction

There are some basic checks and simple modifications that can be made to significantly improve the cooling system in any Lotus Elan.

First check what type of radiator is installed in the vehicle.

This may sound rather obvious but with the passage of time, various types of radiators may have been substituted.

These may or may not be capable of providing adequate cooling.

The original Elan and Elan +2 radiators have a two core construction.

This means that two rows of vertical cooling tubes run through the cooling matrix.

This can be checked by removing the radiator cap and counting the number of rows visible at the top of the radiator tank.

The rows are usually staggered and should be counted across the cooling matrix (from front to rear).

It is also possible to up rate the radiator capacity by changing the standard two cores to a three core construction.

This simple modification is recommended in warmer climates or if the engine has been modified to produce more power.

Radiator types

During production there were several radiators that were fitted to the Lotus Elan and Lotus Elan +2.

The following list provides part numbers and models to receive these components.

026K0001 – fitted to Lotus Elan S1, S2, up to chassis number 5810 (bottom fastening)

A026K0001 – fitted to Lotus Elan S3, from chassis number 5811 to 7894 (full width @ 22 inches, with side fastening)

A050K0001 – fitted to Lotus Elan S4, from chassis number 7895 onwards (narrow @ 16 inches, with side mounting brackets)

A026K0001 – fitted to Lotus Elan +2, up to chassis number 0927 (full width @ 22 inches, with side fastening)

A050K0001 – fitted to Lotus Elan +2s, from chassis number 0928 onwards (narrow @ 16 inches, with side mounting brackets)

Note- As the engine horse-power increased, radiator sizes got smaller and pressure caps were increased from 7lbs to 10lbs

Radiator sizes

Dimensions for radiator part number A050K0001 are as follows-

Overall height (bottom to top tank) is 340mm

Total height (including guard at the filler cap, if fitted) is 365mm

Width is 406mm (16 inches)

Active cooling matrix dimensions are 380mm x 250mm

From experience, it is still possible to obtain a high quality copper matrix that has three cores to provide additional cooling.

Be sure to ask for a copper matrix that has sixteen fins per inch so maximum cooling is achieved.

Radiator performance

To check the radiator performance, first run the engine until it reaches normal operating temperature.

By comparing the temperature differential between the inlet and the outlet, it is possible to assess the cooling efficiency.

With the engine at idle speed and the thermostat fully open, there should be a temperature difference of least 10 degree Centigrade.

This can easily be checked by use of a hand held, non-contact, infra-red thermometer.

Raytek manufacture an inexpensive unit known as a MiniTemp MT4.

This hand held instrument is easy to use and has a back-light digital display and incorporates a laser pointer.

Alternatively there are adapters available from Fluke Instruments that will convert their range of multi-meters into a contact type digital thermometer.

Thermostat

If the engine is showing signs of overheating, then one of the simplest tasks to carry out is to reverse flush the radiator and the rest of the cooling system.

The use of a flushing agent is also recommended as this removes calcified deposits which reduce heat transfer.

Lotus originally fitted several different thermostats to both the Lotus Elan and Lotus Elan +2.

The following list provides details of the part numbers and opening temperatures.

036E6002 thermostat – 88 degrees Centigrade

036E6003 thermostat – 71 degrees Centigrade

036E6022 thermostat – 78 degrees Centigrade

It is important to install the correct thermostat to suit climatic conditions otherwise the engine can not operate at its optimum running temperature.

To illustrate this point, interior cabin heaters will not function correctly during the cold winter months (temperatures of zero degrees and below in the Northern Hemisphere) if a 74 degree thermostat is fitted.

In simple terms this means, the engine cannot reach its designed operating temperature when a lower opening temperature thermostat fitted.

For warmer climates such as in Australia, it is recommended a 71 or 74 degree Centigrade unit be installed.

This phenomenon brings about the change and use of a “winter thermostat” and a “summer thermostat”.

Check and make sure there is a thermostat installed in the housing.

The cooling system needs a thermostat to modulate the flow of water to keep the cylinder head at an optimum operating temperature.

Check that the thermostat opens fully when placed in a pan of boiling water.

Quick opening thermostats such as WAXSTAT are highly recommended.

Thermostat specifications and testing

A thermostat that has a stamped marking of 82°C , relates to the crack point of the thermostat or when it begins to open, (SAE specification has a + / - 2.5°C tolerance on this temperature).

The fully open temperature is usually 12°C above the crack point (i.e. for a 82°C this will be approx 94°C)

The fully open position is the maximum opening position of the thermostat and should ¼ the size of the thermostat orifice (i.e. if the orifice of the thermostat is 20mm then maximum opening will only be 5mm)

During installation it is important that the correct coolant mix is used and all air is removed from the cooling system.

The thermostat requires liquid around the bulb to ensure an even temperature rise so the thermostat can open smoothly and at the correct temperature.

Air locks behind the thermostat may cause the thermostat to open at the incorrect temperature and or open and close quickly (shuddering).

A thermostat may be tested by suspending it by a thread through the orifice in cool water / coolant.

The water / coolant must be heated gradually to simulate the vehicle operation.

The thermostat will fall from the thread once the opening temp has been achieved.

See above for opening temp and maximum opening details.

NOTE: The thermostat should be replaced if it fails to open at a temperature greater than 6°C above or opens 3°C below the designated opening temperature.

Fans

To improve cooling efficiency, remove the plastic or metal fan fitted to the water pump drive flange and fit an electric thermostatically controlled fan.

When fitting an electric fan to an Elan or Elan +2, make sure the fan is offset towards the passenger side of the radiator.

Lotus got this position right on the S4 Elan and the Elan +2 S130.

Off-set mounting the fan in this way provides useful additional cooling to the alternator.

In addition to this, the air flow continues over the exhaust manifold and assists in reducing under bonnet temperatures.

Checking fans

Check and make sure the electric fan(s) rotates in the correct direction.

It should pull air in from the front of the vehicle and blow it through the radiator, where it should exit rearwards around the engine.

Also check the operating temperatures at which the thermostatically operated switch opens and closes.

The standard fan switch is known as an “Otter Switch”.

This same switch is also fitted to the Lotus Esprit, Elite and Eclat.

This switch is still available and can be purchased from Lotus Marques.

Otter switch – standard opening and closing temperatures

87 degrees C it closes and switches on the electric fan

82 degrees C it opens and switches off the electric fan

Intake airflow

Make sure the lower blanking panel is in place between the body and the bottom of the radiator (this should cover the steering rack).

The Lotus part number for the Elan lower blanking panel is B036K0076 and the Lotus part number for the Lotus Elan +2 is A050K0081.

So many of these panels which were originally manufactured from cardboard that was impregnated with Bitumen have rotted away or have been discarded.

Once removed, a vast amount of incoming air is allowed to escape between the bottom of the radiator and fibreglass panel located on top of the steering rack mounting.

Aluminium blanking panel available from Lotus Marques

Aluminium blanking panel available from Lotus MarquesIf you have the original remote air filter and canister, relocate this so it’s lying down instead of standing upright and obscuring the radiator.

Stick a soft foam rubber strip across underside of the bonnet lid so when it closes it seals the gap between the bonnet and the top of the radiator.

The idea is to force all the incoming air through the radiator and not allow any to escape around it.

Imroving the cooling system on a Lotus Elan +2

Lotus recognised there were cooling issues and the workshop manual contains the following useful information-

PAGE 12 SECTION K - COOLING SYSTEM

To further improve the cooling system, 'Sl30‘ models were fitted with a blanking panel (Part No. A050K0081) below the radiator, and panels at each side of the

radiator (Part No. A050K0082 R/H; A050KO083 L/H).

ln conjunction with the blanking panels, foam rubber strips (Part number A05K0084 L/H; A050K0085 R/H), are attached to the underside of the bonnet.

Temperature gauges

The Lotus Elan is fitted with a dual gauge which incorporates the temperature gauge and oil pressure.

The temperature gauge is a capillary type and is reasonably accurate.

This needs to be installed carefully as the copper tube is prone to being damaged.

The Lotus Elan +2 is different as it is fitted with an electrical type temperature gauge.

The temperature gauge is operated by a temperature sender unit located in the cylinder head/thermostat housing.

Checking temperature gauges

Check the gauge reading against a hand held thermometer.

These devices are quick and accurate to use.

The MiniTemp MT4 can simply be pointed directly at the thermostat housing to obtain an instant engine temperature reading.

An alternative check is to remove the radiator cap (when the engine is cold) place a cooking thermometer in the top of the radiator and warm the engine up.

Check the thermometer reading against the vehicle gauge reading.

The original electrical temperature gauge and transmitter fitted to the Lotus Elan +2 and Lotus Elan +2s 130/5 are not very accurate.

Running a basic test on one particular Lotus Elan +2s 130/5 revealed the temperature gauge read eight degrees too high.

Fortunately it is better that the gauge reads too high than too low as this usually prompts the owner to take action.

The instrumentation in early Lotus vehicles is very basic.

How many Lotus owners ever think about checking the accuracy of these important devices?

Smiths Industries in the UK manufactured the original temperature transmitter.

Alternative temperature transmitters offered by companies such as VDO are incorrectly substituted.

Incorrectly substituted VDO temperature transmitter

Incorrectly substituted VDO temperature transmitterThe direct result of this will cause the temperature gauge to give a false reading, indicating the engine is either overheating or not up to normal operating temperature.

The temperature transmitter has a negative co-efficient characteristic.

In other words the resistance decreases as the temperature increases.

A comparison between a VDO and Smiths temperature transmitter is shown in the graph below.

Note: A small change in resistance represents a significant change on the temperature gauge reading.

This point illustrates why the correct component should always be installed.

Temperature transmitter characteristics

Temperature gauge and voltage stabiliser

The accuracy of the temperature gauge is influenced by the original mechanical vibrating contact type voltage stabiliser.

This device is crude as it generates a square wave output in an attempt to stabilise a constantly fluctuating battery voltage when the alternator is driven by the engine.

On a Lotus Elan 2+2, both the fuel gauge and and temperature gauge share the output from the same voltage stabiliser.

Eventually the voltage stabiliser vibrating contacts wear out which in turn causes the fuel and temperature gauge to read incorrectly.

If for any reason both the fuel gauge and temperature gauge are suspected of not reading correctly then its wise to check the voltage stabiliser.

Voltage measurements must be carried out using a True RMS Digital Multi-Meter (DMM) otherwise inaccurate readings will result.

Note carefully, not all DMM's are created equal and for this reason we choose to use high quality Fluke meters.

An inexpensive replacement solid-state voltage stabiliser can be constructed using the following components shown in the circuit below.

This circuit is inherently stable when subjected to a fluctuating battery voltage and changes in ambient temperature.

The same circuitry can also be used in the later Lotus Esprit (1980 onwards) that employ Smiths instruments.

Note - A correctly operating temperature sender unit should have a resistance reading of approximately 100 Ohms at 85 degrees Centigrade.

Water pump

If the water temperature continues to rise up at speed, then there are a number of items that should be checked.

Firstly, the Lotus twin cam water pump should be checked that it is not cavitating at high speed.

To do this, a water pump efficiency test should be carried out.

If the pump is cavitating then it will not produce the necessary head to move the water around the system.

Other items that influence water pump efficiency, is whether the impellor gap has been set correctly when the water pump was last rebuilt.

The water pump drive belt should also be checked for serviceability and that it is adjusted to the correct tension.

Water pump leaking from weep hole

If there is any coolant originating from the weep hole, this is a sure sign of internal seal failure.

The service life of the seal can be significantly extended by performing regular maintenance of your cooling system.

Periodic checks of hoses and the recovery tank will assure coolant levels are correctly maintained.

The correct coolant level ensures that there no atmospheric contaminants that can cause oxidation and sludge build-up in the cooling system.

Sludge build-up in the cooling system is the primary cause of seal failure as well as reducing cooling system efficiency.

Servicing the radiator

Check that the radiator fins are not blocked externally.

It may be necessary to clean the radiator with a high pressure cleaner.

Apply the pressure cleaner from inside the engine bay so it blows the trapped debris outwards to the front of the vehicle (the opposite direction to which they entered).

It is amazing how much rubbish gets trapped in a radiator and reduces its efficiency.

Inspect the condition of the black paint after pressure cleaning the radiator, you may find that sheets of paint may have peeled off.

Repaint the radiator with a good quality matt black paint.

This dramatically improves the efficiency or rate at which the radiator dissipates radiant heat.

Lotus Marques highly recommends Wattyl spray pack paint for repainting tired or refurbished copper radiators.

The product to look for is Wattyl Killrust High Heat Enamel and is ideal for radiators as it offers the following benefits -

- Fast drying, satin black finish

- Provides heat resistant protection to interior and exterior metal surfaces exposed to heat up to 650ºC

- Does not require a primer and is ideal for BBQ hoods and engine exhaust components

For more information about this excellent product, visit the Wattyl web site here

Radiator cap

Ensure that the radiator cap is in good working order and tested to recommended pressure rating.

The radiator cap is an extremely important component in the cooling system, a faulty cap can cause overheating through the incorrect pressure rating and or loss of coolant.

Check that the correct pressure cap is installed.

Check if the cap is leaking and whether the rubber seal is serviceable.

Check the cap plunger length is correct for the radiator neck.

Early cars had a cap rated at 7lbs but this was later upgraded to 10lbs.

If the cooling system is loosing water and the pressure cap is found to be serviceable, then there is the possibility that the problem is a leaking head gasket.

This will cause the system over pressurise and dump water.

Faulty head gasket

A leaking head gasket will cause overheating problems by displacing coolant whilst the cooling system is attempting operate at normal pressure.

The easy way to check for a leaking head gasket is to carefully remove the cap and look for air bubbles whilst the engine is running.

If you have access to a gas analyser, then this can be used to check the contents of the bubbles for exhaust gases.

Alternatively a leak down tester may be used to introduce compressed air into the cylinders one at a time.

Again remove the radiator cap and look for bubbles to determine if the head gasket is leaking.

Coolant check

If over heating persists, then use a hydrometer to check the coolant concentration.

It is possible to have a significantly concentrated glycol solution in your cooling system and this will cause the engine to over-heat.

To illustrate this point, plain water has twice the heat transfer capability compared to 50% glycol antifreeze/coolant in water.

Empty the system of glycol, flush, then refill with water and check the system performance again.

For superior results, install Redline Water Wetter in your cooling system to further reduce cylinder head temperatures.

In race applications, the use of Water Wetter will allow the use of smaller and subsequently lighter weight cooling system components.

Engine modifications

If an engine is modified for race purposes, then be aware of the following calculations.

If you are going to raise the horse power of the engine by say 10bhp (this may not seem a lot) but it has a significant impact on the cooling system.

Ten brake horse power equates to approximately 7500 watts off energy.

If you have a reasonably efficient engine, then it will convert about a 33% of the available energy in to useful energy at the flywheel.

Another 33% will disappear out of the exhaust pipe and the remaining 33% will be dissipated by the cooling system.

This means the cooling system has to be capable of dumping an additional 2500 watts of energy.

This is equivalent to the heating capacity a domestic electric kettle.

Additional cooling

For performance modifications or operation in hotter climates, it is recommended that a ten or thirteen row oil cooler be fitted to engines.

This simple modification provides significant additional cooling to all the engine components.

Heat-Soak Pump

The addition of a heat soak pump is a useful way of improving engine reliability.

This simple but effective modification will minimise the risk of warping the alloy cylinder head.

The introduction of a 12 Volt boat bilge pump into the heater hose circuit would produce the desired results.

This could be easily connected to the Otter switch to control the temperature when the pump turns on and off.

A similar heat soak pump is installed on the Lotus Elan M100 as standard equipment and is manufactured by Bosch, part number 0-130-002-066.

About the author

Steve Taylor: is the business owner of Lotus Marques who has a multi-discipline background. This includes 12 years engineering experience gained whilst working on weapon systems design and development for UK Department of Defence. He has also worked for 7 years in a cutting-edge American super-computer company Gould CSD as the UK southern region support manager. During this time he developed a passion for Lotus Cars and motor racing at Brands Hatch Racing School. Emigrating from the UK to Australia in 1987, where in 1992 Lotus Marques commenced trading as a specialist parts supplier. The business offers log-book servicing and repairs as well as designing and manufacturing a range of high quality components to support Lotus owners world-wide.

Copyright © 2011 Lotus Marques